Kodi Kuwotcherera N'chiyani?

The kuwotcherera mphamvu zitsulo amatanthauza kusinthika kwa zinthu zitsulo ndi ndondomeko kuwotcherera, makamaka amatanthauza kuvutika kupeza apamwamba welded mfundo pansi zinthu zina kuwotcherera ndondomeko.Mwachidule, lingaliro la "kuwotcherera luso" limaphatikizaponso "kupezeka" ndi "kudalirika".Kuthekera kwa weld kumatengera mawonekedwe azinthu komanso momwe zinthu zimagwiritsidwira ntchito.The kuwotcherera mphamvu zipangizo zitsulo si malo amodzi koma akufotokozera Mwachitsanzo, kwa zipangizo zimene poyamba ankaona kuti ndi osauka luso kuwotcherera, ndi chitukuko cha sayansi ndi luso, njira zatsopano kuwotcherera zakhala zosavuta kuwotcherera, ndiko kuti, luso kuwotcherera. wakhala bwino.Choncho, sitingathe kusiya ndondomeko zinthu kulankhula za weld luso.

Weld luso zikuphatikizapo mbali ziwiri: mmodzi ndi olowa ntchito, ndiye tilinazo kupanga kuwotcherera zilema pansi zinthu zina kuwotcherera ndondomeko;chachiwiri ndi ntchito zothandiza, ndiko kuti, kusinthasintha kwa welded olowa kuti ntchito zofunika pa zinthu zina kuwotcherera ndondomeko.

Njira Zowotcherera

1.Kuwotcherera kwa laser(LBW)

2.akupanga kuwotcherera (USW)

3. Diffusion welding (DFW)

4 ndi zina

1.Kuwotchera ndi njira yolumikizira zipangizo, nthawi zambiri zitsulo, potenthetsa malo mpaka kusungunuka ndikuwalola kuti azizizira ndi kulimbitsa, nthawi zambiri ndi kuwonjezera zinthu zodzaza.Kuwotcherera kwa zinthu kumatanthawuza kuthekera kwake kowotcherera pansi pamikhalidwe ina, ndipo zimatengera mawonekedwe azinthu komanso njira yowotcherera yomwe imagwiritsidwa ntchito.

2.Weldability akhoza kugawidwa m'zigawo ziwiri: ntchito limodzi ndi ntchito zothandiza.Olowa ntchito amatanthauza tilinazo kupanga kuwotcherera zilema pansi zinthu zina kuwotcherera ndondomeko, pamene ntchito zothandiza amatanthauza kusinthasintha kwa welded olowa ndi zofunika ntchito pansi pa zinthu zina kuwotcherera ndondomeko.

3.Pali njira zosiyanasiyana zowotcherera, kuphatikizapo laser kuwotcherera (LBW), kuwotcherera kwa ultrasonic (USW), ndi kuwotcherera kufalikira (DFW), pakati pa ena.Kusankha njira yowotcherera kumatengera zida zomwe zikulumikizidwa, makulidwe a zida, mphamvu yolumikizirana yofunikira, ndi zina.

Kodi kuwotcherera kwa laser ndi chiyani?

Kuwotcherera kwa laser, komwe kumatchedwanso laser beam kuwotcherera ("LBW"), ndi njira yopangira momwe zidutswa ziwiri kapena zingapo (nthawi zambiri zitsulo) zimalumikizana pogwiritsa ntchito mtengo wa laser.

Ndi njira yosalumikizana yomwe imafuna mwayi wopita ku weld zone kuchokera mbali imodzi ya magawo omwe amawotcherera.

Kutentha kopangidwa ndi laser kumasungunula zinthu kumbali zonse ziwiri za cholumikizira, ndipo zinthu zosungunuka zikasakanikirana ndikukhazikika, zimaphatikiza zigawozo.

Kuwotcherera kumapangidwa ngati kuwala kwakukulu kwa laser kumatenthetsa zinthuzo - zomwe zimawerengedwa mu milliseconds.

Mtengo wa laser ndi wolumikizana (gawo limodzi) kuwala kwa wavelength imodzi (monochromatic).Mtsinje wa laser uli ndi kusiyana kwa mtengo wotsika komanso mphamvu zambiri zomwe zimapangitsa kutentha kukafika pamwamba

Monga mitundu yonse yowotcherera, tsatanetsatane wake amafunikira mukamagwiritsa ntchito LBW.Mutha kugwiritsa ntchito ma lasers osiyanasiyana ndi njira zosiyanasiyana za LBW, ndipo pali nthawi zina pomwe kuwotcherera kwa laser sikuli koyenera.

Kuwotcherera kwa Laser

Pali mitundu itatu ya kuwotcherera laser:

1. Njira yoyendetsera

2.Mayendedwe / njira yolowera

3.Kulowetsa kapena keyhole mode

Mitundu iyi ya kuwotcherera kwa laser imagawidwa ndi kuchuluka kwa mphamvu zomwe zimaperekedwa kuchitsulo.Ganizirani izi ngati milingo yotsika, yapakatikati, komanso yamphamvu kwambiri yamagetsi a laser.

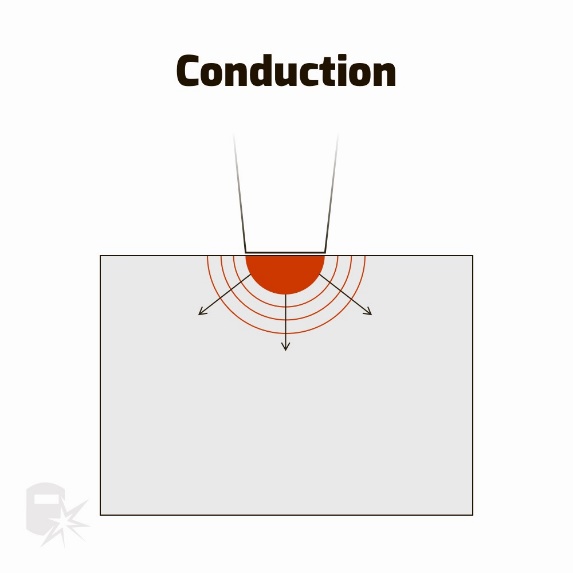

Mayendedwe Mode

Njira yoyendetsera imapereka mphamvu yotsika ya laser kuchitsulo, zomwe zimapangitsa kulowa pang'ono ndi weld wozama.

Ndi bwino mafupa kuti safuna mphamvu mkulu monga zotsatira ndi mtundu mosalekeza malo kuwotcherera.Ma welds oyendetsa ndi osalala komanso owoneka bwino, ndipo amakhala okulirapo kuposa akuya.

Pali mitundu iwiri ya conduction mode LBW:

1. Kutentha kwachindunji:Mbali ya gawoli imatenthedwa mwachindunji ndi laser.Kutentha kumayendetsedwa muzitsulo, ndipo mbali zina zazitsulo zimasungunuka, kusakaniza mgwirizano pamene chitsulo chakhazikika.

2.Kutumiza kwa Mphamvu: Inki yapadera yoyamwitsa imayikidwa koyamba pamalo olumikizirana.Inki imeneyi imatenga mphamvu ya laser ndipo imatulutsa kutentha.Chitsulo chapansi pake chimachititsa kuti kutentha kukhale kagawo kakang'ono kwambiri, komwe kamasungunuka, n'kukhazikika kuti apange cholumikizira chowotcherera.

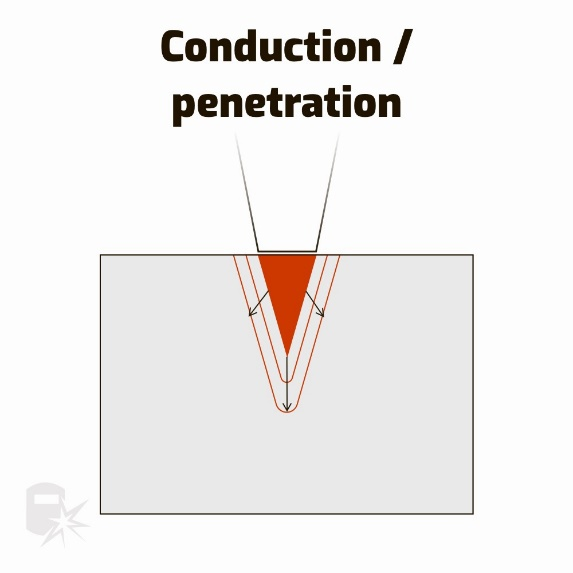

Mayendedwe/Malowedwe Olowera

Ena sangavomereze izi ngati imodzi mwama modes.Amaona kuti pali mitundu iwiri yokha;mwina mumatenthetsa muzitsulo kapena mumatenthetsa kanjira kakang'ono kachitsulo, kulola laser kulowa muchitsulo.

Koma njira yoyendetsera / kulowa imagwiritsa ntchito mphamvu "yapakatikati" ndipo imabweretsa kulowa kwambiri.Koma laser ilibe mphamvu zokwanira kuti isungunuke chitsulo ngati munjira ya keyhole.

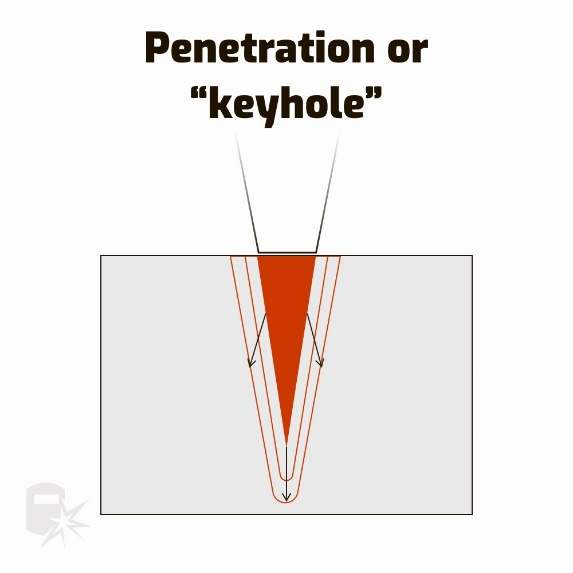

Kulowa Kapena Keyhole Mode

Njira iyi imapanga ma welds akuya, opapatiza.Kotero, ena amachitcha njira yolowera.Ma welds opangidwa nthawi zambiri amakhala ozama kuposa otakata komanso amphamvu kuposa ma welds a conduction.

Ndi mtundu uwu wa kuwotcherera kwa LBW, laser yamphamvu kwambiri imatulutsa nthunzi m'munsi mwachitsulo, ndikupanga ngalande yopapatiza yotchedwa "keyhole" yomwe imafikira pansi."Bowo" ili limapereka ngalande kuti laser alowe mkati mwachitsulo.

Zitsulo Zoyenera Za LBW

Kuwotcherera kwa laser kumagwira ntchito ndi zitsulo zambiri, monga:

- Chitsulo cha Carbon

- Aluminiyamu

- Titaniyamu

- Low alloy ndi chitsulo chosapanga dzimbiri

- Nickel

- Platinum

- Molybdenum

Akupanga kuwotcherera

Akupanga kuwotcherera (USW) ndiko kujowina kapena kukonzanso kwa thermoplastics pogwiritsa ntchito kutentha komwe kumapangidwa kuchokera kumayendedwe apamwamba kwambiri.Zimatheka potembenuza mphamvu yamagetsi yamagetsi apamwamba kwambiri kuti ikhale yothamanga kwambiri.Kuyenda kwamakinako, limodzi ndi mphamvu yogwiritsira ntchito, kumapangitsa kutentha kokangana pamalo okwerera a pulasitiki (malo olumikizana) kotero kuti zinthu zapulasitiki zimasungunuka ndikupanga mgwirizano wa mamolekyulu pakati pa zigawozo.

MFUNDO YOYENERA KUTI ULTRASONIC WELDING

1.Parts mu Kukonzekera: Zigawo ziwiri za thermoplastic zomwe ziyenera kusonkhanitsidwa zimayikidwa palimodzi, chimodzi pamwamba pa chinzake, mu chisa chothandizira chotchedwa fixture.

2.Ultrasonic Horn Contact: Titaniyamu kapena chigawo cha aluminium chotchedwa nyanga chimabweretsedwa ndi gawo lapamwamba la pulasitiki.

3.Force Yogwiritsidwa Ntchito: Mphamvu yolamulidwa kapena kukakamizidwa kumagwiritsidwa ntchito pazigawozo, kumangiriza pamodzi motsutsana ndi kukonza.

4.Weld Time: Nyanga ya akupanga imagwedezeka 20,000 (20 kHz) kapena 40,000 (40 kHz) nthawi pa sekondi iliyonse, pamtunda woyezedwa mu zikwi za inchi (microns), kwa nthawi yodziwikiratu yotchedwa weld time.Kupyolera mwa kusamala mbali kamangidwe, izi kugwedera makina mphamvu umalunjika kwa mfundo zochepa kukhudzana pakati pa mbali ziwiri.Kugwedezeka kwamakina kumapatsirana ndi zida za thermoplastic kupita kumalo olumikizirana kuti apange kutentha kwamphamvu.Pamene kutentha kwa mawonekedwe olowa kumafika posungunuka, pulasitiki imasungunuka ndikuyenda, ndipo kugwedezeka kumayimitsidwa.Izi zimathandiza kuti pulasitiki yosungunuka iyambe kuzizira.

5.Hold Time: Mphamvu yokhotakhota imasungidwa kwa nthawi yokonzedweratu kuti zigawozo zigwirizane pamene pulasitiki yosungunuka imazizira ndikukhazikika.Izi zimatchedwa nthawi yogwira.(Zindikirani: Kupititsa patsogolo mphamvu zamagulu ndi hermeticity kungapezeke mwa kugwiritsa ntchito mphamvu yapamwamba panthawi yogwira ntchito. Izi zimatheka pogwiritsa ntchito mphamvu ziwiri).

6.Horn Retracts: Pulasitiki yosungunuka ikakhazikika, mphamvu ya clamping imachotsedwa ndipo nyanga ya akupanga imachotsedwa.Zigawo ziwiri zapulasitiki tsopano zimagwirizanitsidwa ngati kuti zimapangidwira pamodzi ndipo zimachotsedwa pazitsulozo ngati gawo limodzi.

Diffusion Welding, DFW

Njira yolumikizirana ndi kutentha ndi kuthamanga komwe malo olumikizana amalumikizana ndi kufalikira kwa ma atomu.

Njira

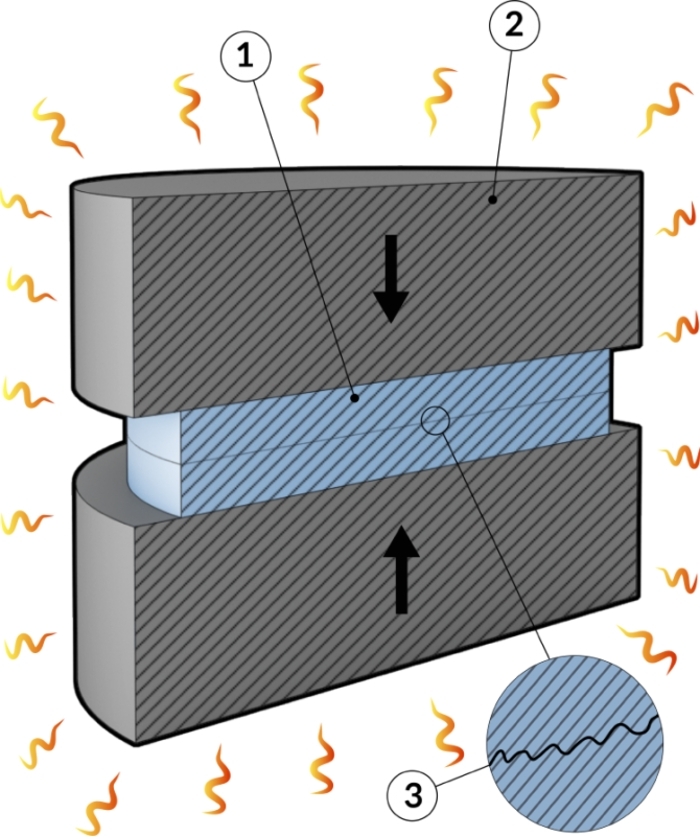

Zida ziwiri zogwirira ntchito [1] pamagulu osiyanasiyana zimayikidwa pakati pa makina awiri osindikizira [2].Makina osindikizira ndi apadera pazophatikizira zilizonse zogwirira ntchito, chifukwa chake ndikofunikira kupanga mapangidwe atsopano ngati kapangidwe kazinthu kakusintha.

Kutentha kofanana ndi pafupifupi 50-70% ya zinthu zomwe zimasungunuka zimaperekedwa ku dongosolo, ndikuwonjezera kuyenda kwa maatomu azinthu ziwirizo.

Makinawo amakanikizidwa palimodzi, zomwe zimapangitsa kuti maatomu ayambe kufalikira pakati pa zida zomwe zili pamalo olumikizirana [3].Kufalikira kumachitika chifukwa cha ntchito zomwe zimakhala zosiyana, pamene kutentha ndi kupanikizika kumangopangitsa kuti ntchitoyi ikhale yosavuta.Kupanikizika kumagwiritsidwa ntchito kuti zinthu zolumikizana nazo zikhale pafupi kwambiri kuti maatomu athe kufalikira mosavuta.Pamene gawo lofunidwa la ma atomu lifalikira, kutentha ndi kupanikizika kumachotsedwa ndipo kugwirizanitsa kumatsirizidwa.